Introduction

Selecting the right industrial glass is critical for ensuring safety, performance, and longevity in industrial operations. From monitoring fluid levels in boilers to handling corrosive chemicals in reactors, the choice of glass can significantly impact operational efficiency and safety.

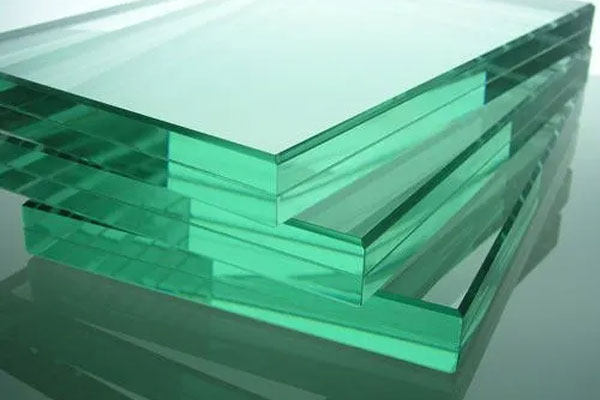

With numerous types of glass available — such as borosilicate, toughened, reflex, and high-temperature variants — making the right decision can be challenging. Choosing the wrong type may lead to breakage, chemical contamination, or process inefficiencies, which can be costly and dangerous.

At Glazients Glasstech Pvt. Ltd., we provide customized, precision-engineered industrial glass solutions to help industries achieve reliability, safety, and operational excellence.

Identify the Industrial Environment

The first step in selecting industrial glass is understanding the operating environment:

- Temperature Range – High-temperature processes require toughened or borosilicate glass.

- Pressure Conditions – High-pressure systems need mechanically strong and shatter-resistant glass.

- Chemical Exposure – Chemical plants require corrosion-resistant glass, such as borosilicate.

- Mechanical Stress – Areas with potential impact need toughened or laminated glass.

Knowing the operating conditions ensures you select a glass type that can withstand stress, temperature, and chemical exposure.

Consider Safety Requirements

Industrial glass must adhere to safety standards:

- Breakage Behavior – Toughened glass breaks into small blunt pieces, reducing injury risk.

- Thermal Shock Resistance – Prevents cracking under rapid temperature changes.

- Chemical Resistance – Prevents corrosion or contamination in chemical and pharmaceutical applications.

Glass chosen for safety-critical environments must meet international industrial standards to prevent accidents and ensure operational reliability.

Conclusion

Selecting the right industrial glass is a critical step for ensuring safety, reliability, and operational efficiency. Understanding the environment, pressure, temperature, chemical exposure, and monitoring needs helps in choosing the appropriate glass type — whether it’s borosilicate, high-temperature toughened, reflex, or flange glass.

At Glazients Glasstech Pvt. Ltd., we provide customized, precision-engineered industrial glass solutions tailored to meet diverse industry needs. Our products are durable, chemically resistant, and thermally stable, making them the preferred choice for chemical, pharmaceutical, boiler, engineering, and oil & gas industries.

For industrial operations that demand clarity, strength, and safety, trust Glazients Glasstech Pvt. Ltd. to deliver industrial glass solutions that last and perform.